That is how we will construct paved roads on the moon

The moon is ready to be our subsequent frontier. When Artemis 3 launches (tentatively) towards the tip of 2025, it will likely be the primary mission because the Apollo period to land people on our satellite tv for pc. By then, there could also be a brand new strategy to sift by means of the moon’s grey mud, which may a minimum of mitigate the injury brought on by sharp particles from lunar regolith.

A world staff of researchers on the European House Company paving The undertaking has found a strategy to soften moon mud — or a minimum of a stimulant developed by the European House Company — utilizing lasers. Researchers fired lasers at lunar soil to create interlocking pavers that may very well be used to construct paved roads and touchdown pads. The hardened molten regolith is robust sufficient to help the load of spacecraft and different spacecraft with minimal mud, and may very well be totally manufactured proper there on the Moon.

“This expertise is anticipated to play a significant function within the first (survival) section of lunar infrastructure and base improvement, and over time to contribute to all phases of lunar exploration,” the researchers mentioned in a examine not too long ago printed within the journal. Scientific reports.

Scratch the floor

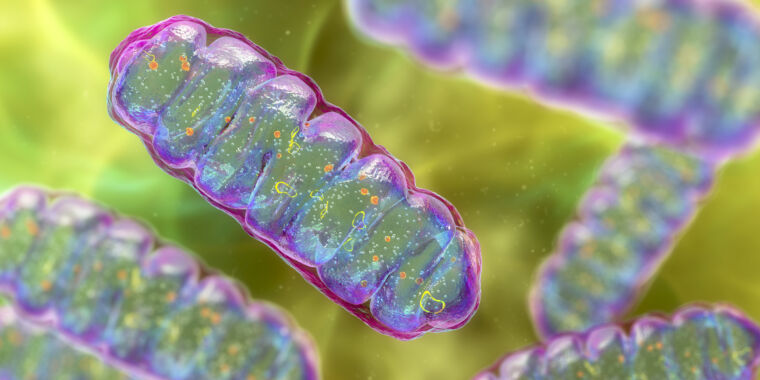

Moondust has been the bane of spacecraft and lunar astronauts for a purpose. On Earth, rocks, glass, and different supplies within the soil are continually uncovered to weathering forces akin to wind, rain, and flowing water, which is why sand grains are sometimes easy across the edges. The lunar regolith is hardly affected by climate elements because of the lack of wind and liquid water. Any spacecraft that lands on or transits the Moon is in danger from the mud it kicks up, as a result of fragments of rock and glass that haven’t been uncovered to the weather can simply scratch delicate devices and corrode surfaces. The low gravity on the Moon additionally implies that turbulent fragments preserve flying off and stepping into every part.

PAVER scientists needed to plot a strategy to create paving supplies from assets already accessible on the Moon. Transport provides from Earth is pricey and inconvenient, due to this fact On website Manufacturing is most popular each time potential.

The principle distinction in these simulation experiments (moreover the regolith simulation) was that the CO22 Lasers had been used to warmth the fabric as an alternative of the concentrated photo voltaic gentle that astronauts would use on the Moon.

Stepping stones

Lasers of various sizes and powers should be examined to seek out the kind that produces the strongest paving supplies. Throughout this course of, the analysis staff discovered that any intersection or interference of laser beams may result in inside cracking, particularly since Lunar regolith Crammed with glass and different silicates. The laser that proved efficient ended up having a forty five mm (about 1.8 inch) beam that would transfer over the mud in a selected sample that created triangular shapes. He melted the regolith simulation into 250 mm (practically 10 inch) items that had been 15 mm (simply over half an inch) thick and will simply interlock with one another. Naturally, it must be scaled up for precise lunar operations to accommodate precise spacecraft.

The regolith that has been irradiated and cooled consists of three totally different layers. The highest layer, a sort of glass, was melted, and the crystallized materials within the center layer was melted. The skinny layer of fabric beneath was calcified reasonably than dissolved, which means it was the product of mud caught collectively in a porous mass. Whereas this materials was dense and powerful sufficient by itself, the geometric shapes the scientists designed had been supposed to extend its flexibility and resistance to cracking or breaking.

To see if they might help the load of a spacecraft, the triangles had been subjected to strain assessments to see how a lot strain they might take earlier than they broke, the very best strain being 216.29 megapascals (simply over 30,000 kilos per sq. inch). For comparability, the Apollo Lunar Module weighed 33,000 kilos, and its weight was distributed over a couple of inch.

Scientists acknowledge that there’s nonetheless progress to be made on this analysis. A lens to focus daylight would exchange the laser on the Moon, so it will should be examined. Nonetheless, these assessments are value pursuing, as solely a small quantity of light-weight tools is required to hold out this course of on the Moon. It could even be potential to get them there in time to stroll on the moon once more since Apollo 17.

Scientific Experiences, 2023. DOI: 10.1038/s41598-023-42008-1